Injector Servicing

Injector cleaning

(from $36.00+gst per injector)

As a price guide most std back feed type injectors cost $30.00+gst to clean and require a $6.00+gst kit (filters,seals and pintles)$36.00+gst

As a price guide most side feed type injectors cost $30.00+gst to clean and require a $30.00+gst kit (filters,seals and pintles)$60.00+gst

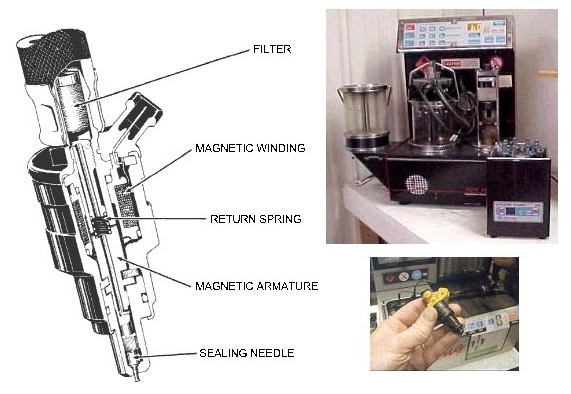

The Problem Most modern petrol cars today suffer from injector fouling to various degrees. This is due to additives (lacquers) and dirt in the fuel which tend to build up in the passage ways and in the nozzle but often more seriously, the lacquers block the filter which is located inside the housing. This filter is located at the inlet of the injector and is extremely fine thus any build up of contamination can cause a reduction in the flow of fuel. The other area most affected is the nozzle itself, this is not helped by the harsh environment it is situated in. Injectors are usually located in the inlet manifold so that the spray from the nozzle is directed at the inlet valve and therefore contamination from the breather system along with the heat also adds to the problem. Today especially with stricter exhaust emissions required properly working injectors are important. The symptoms of fouled or partially blocked injectors are uneven idle, lack of performance, poor emissions and reduced M.P.G.. It is recommended that they are checked & cleaned or replaced if necessary every 50,000 ks (30,000 miles).

The Solution The cleaning process starts with the injectors being checked for flow rate, spray pattern and leak down to check their performance. All cleaning and testing takes place off the car. The filters and seals are removed, then the injectors are placed in an ultra sonic cleaning tank. They remain in the tank for a hour where all the lacquer deposits are dissolved, after this they are back flushed to remove any larger stubborn particles. Then they are rechecked to make sure that the flow rate spray pattern and leak down are within the manufacturers tolerances. New filters, seals and pintles are fitted before they are sent out.